The bulb tube, the core component of CT, is the lifeblood of the 100 billion image market.

Its advantages and disadvantages can not only determine the performance level of CT machine to a certain extent, but also have been regarded as the key to narrow the gap between high-end products and imported brands.

However, due to the complex technology and high process requirements of CT core components such as ball tube, as well as the problems that most production equipment needs to be customized, this component has not yet been completely localized. For a long time, most domestic video manufacturers have not been able to research and produce core components by themselves, and most of the core components of domestic high-end products are imported products.

April this year,Beijing Smart BeamIt has made a key breakthrough, won the first registration certificate of domestic liquid metal bearing CT tube medical device, and has the capacity of mass production. Now, the liquid metal bearing ball tube independently researched and developed by the enterprise has also entered the pre assembly machine and will soon be supported for certification.

It is reported that Smart Beam has established a complete design and development system from design, materials, processing, assembly to reliability testing, and has a complete product development, iteration and production capacity。

As the first enterprise to obtain CT ball tube of liquid metal bearing in China,,Recent arterial network andSmart BeamHu Yinfu, the founder, conducted an exclusive interview to answer the development trend and key technical points of CT ball tube, and the key research and development issues of liquid metal bearing ball tube.

Break through the technology of liquid metal bearing ball tube,Several CT tubes under development will be approved soon

From the development history of the ball tube technology, the traditional CT ball tube usually uses ball bearings. However, the appearance of liquid metal bearing technology in the 1990s gradually replaced ball bearings and became the mainstream of high-end CT applications in the first two decades of the 21st century.

Compared with traditional ball bearings, liquid metal bearings can bring at least four advantages:

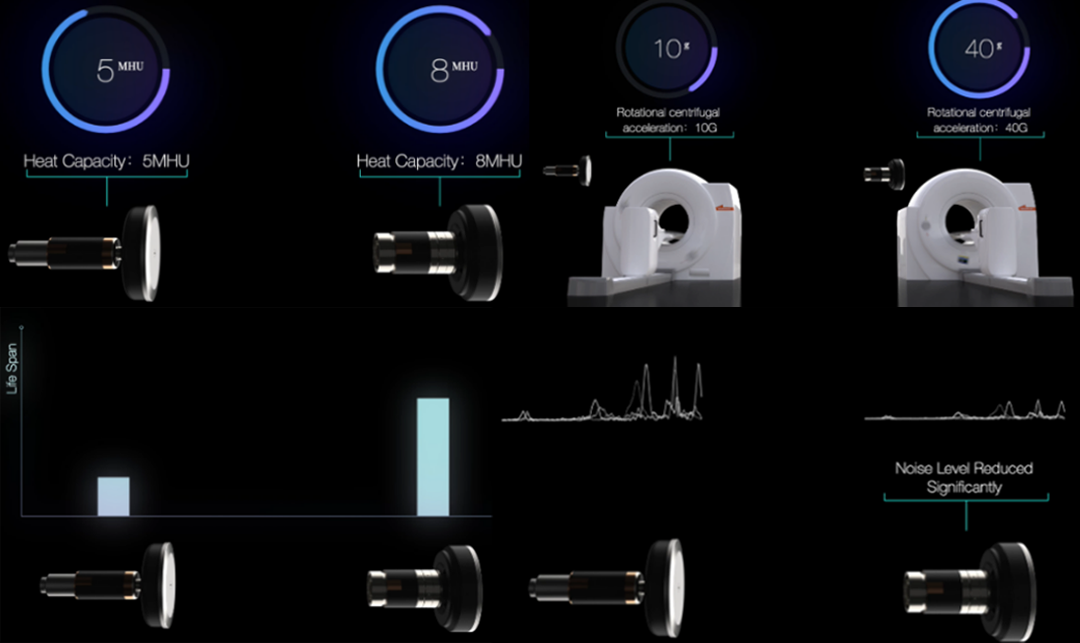

(1) Greatly increase heat dissipation rate. That is, the equivalent heat capacity can be greatly improved under the target disk structure with the same physical heat capacity;

(2) The liquid metal sliding bearing can withstand 30-40g of the centrifugal force of frame rotation, which can support faster frame rotation and imaging speed, and has great advantages for heart scanning;

(3) As the bearing core does not directly contact with the bearing sleeve when the bearing is working, the wear is small, and the service life of the bearing is at least twice that of the ball bearing;

(4) The liquid metal sliding bearing has no contact and belongs to the completely silent operation.

With the continuous maturity of liquid metal bearing technology in recent years and the decline of mass production and manufacturing costs, the application of liquid metal bearing is no longer limited to high-end CT, and it starts to move towards the application of mid end models. Its application scenarios and market space become more and more extensive.

However, the production and manufacturing of key components of liquid metal bearing ball tube involves more than 30 processes. The key technical problems encountered include design, materials, processing, welding, vacuum, surface treatment, precision assembly, etc. It is particularly difficult to break through the key technologies.

Beijing Smart BeamThrough the integration of 3D design of ball tube (mastering Inventor, Solidworks, Pro-E and other tools), electronic optical design simulation (mastering OPERA, CST and other software), electromagnetism, design simulation (mastering CST, Ansys), structural mechanics and thermal design simulation (mastering Ansys, Fluent, etc.), rotor dynamics design simulation and other technologies, the breakthrough in key technologies of liquid metal bearing ball tube was achieved only three years after its establishment, Break the technology monopoly of foreign manufacturers in the field of liquid metal bearing ball tube.

along with Beijing Smart Beam With the process iteration, the first pass rate of CT tube production of liquid metal bearing has reached more than 90%.

Hu Yinfu shared with Arterial Network Smart Beam Bearing process, he said: "Take the key component technology of liquid metal bearing as an example, its production and manufacturing involve complex process links, need to deal with many key technical issues, and each link is related to each other. You need to evaluate the process effect as a whole, rather than looking at whether a process is feasible in isolation.

During the process curing of our ZS502L liquid metal bearing, we have almost gone through dozens of rounds of process iteration and optimization, and the process stability has also reached the level where the one-time pass rate of the current batch production is more than 90% from the earliest sporadic samples can completely pass the test.

In the future, we hope to further narrow the gap with mature CT tube R&D enterprises such as' GPS' through relevant process optimization, and finally realize the home-made surpassing of CT tube technology through independent innovation.”

With nearly 20 years of research and development experience in the field of vacuum electronics, we will continue to focus on the field of CT core components in the future

As the core component of CT, the research and development of the ball tube is not only a long process route, heavy equipment investment, long research and development cycle, and slow to take effect, but also a very typical field that needs multidisciplinary crossing. Therefore, the research and development of CT tube requires a high level of comprehensive quality for the team. A team that has a deep understanding of process optimization and iteration, can reliably research and design, carefully study every process detail in technology, and strictly check every operation step is required.

Hu Yinfu studied in Wuhan University and Tsinghua University successively, and obtained a doctorate in physical electronics. After graduation, Hu Yinfu served as Vice Chairman of IEEE China Committee and MDC Chairman of IEEE Beijing Branch. He has published more than 50 academic papers in academic journals and conferences at home and abroad, and has nearly 20 years of experience in R&D, production and management in the field of vacuum electronics.

"As a technician with a professional background in vacuum electronics, we are still not reconciled to the fact that our product technology has been" stuck "by foreign countries. In this medical field, which is related to the safety and health of people's lives, to be able to solve key technical problems for the development of the domestic industry will give all our team members a high sense of achievement and gain.

I am very proud that our R&D and process engineers can endure hardships and have tenacity. It is normal for the R&D team of Wisdom Beam Technology to stay up all night in the process of optimization and iteration of CT tube process technology. It is common to put a marching bed beside the computer, lie on the marching bed for a while when tired, and then get up again to see the effect of process optimization. Therefore, if there is any secret to overcome the R&D problems, I think it is our attitude of never giving up when facing these technological problems. " Hu Yinfu said.

At present,Smart BeamTwo products have obtained medical device registration certificates, and five CT tubes under development will be approved in 2022。Its self-developed ZS402L cooperates with the registration of a 32 row CT complete machine in China, which has passed the type inspection and on-site system assessment. It is expected to obtain the registration certificate of the complete machine in October 2022, which will be the first complete machine product using domestic liquid metal bearing CT ball tube.

It is reported that Zhishu Technology is still expanding its product pipeline, and the first domestic production and manufacturing center for liquid metal bearings will be officially put into use this year, with the design capacity of 2000 sets of liquid metal bearings per year. The CT ball tube product pipeline under research can cover the mainstream models in the market.

At the same time, the company has carried out in-depth cooperation with Kuanteng Medical, Sanova, Kaiying Medical, Boying Medical, Wandong Medical and other enterprises, such as product customization, new product development, and machine registration. It also established the basis for follow-up cooperation with Lianying Medical, Neusoft Medical and Mingfeng Medical.

In the future, under the environment of policy support, technology upgrading, equipment supplement and capital assistance, Zhibun Technology will continue to increase its R&D investment. At the same time, through continuous efforts, we will provide a full range of high-end CT ball tube products to domestic CT machine manufacturers and third-party maintenance service customers, and strive to achieve full coverage of the main liquid metal bearing ball tube models in the market within three years.

Establish an advantageous position with high cost performance ratio, and promote the domestic substitution process of CT tube with domestic enterprises. We will continue to enhance the ability to control the supply chain of the industrial chain, and truly achieve the goal of controlling the core component technology independently.

Complete the breakthrough from "0" to "1",

Ball tube will usher in a period of rapid development

In 2018, the Configuration License Management Catalog of Large Medical Equipment (2018) redefined the configuration mode of large imaging equipment: 16 row CT and below do not require administrative approval; For the first time, the configuration management right of a single set (set) of large medical devices with a price of 10-30 million yuan, 64 row CT and above, is transferred from the National Health Commission to the provincial health commission.

After the policy, grass-roots medical institutions began to widely purchase 16 row CT, so the whole machine market and replacement market of ball tube ushered in massive growth. The demand for high-end CT is also diversified.

On the one hand, with the substantial increase in the annual turnover of the tertiary hospitals around the country, the pressure on funds to purchase CT has decreased significantly; On the other hand, the rise of independent imaging centers has also set off a wave of high-end CT purchases. By the end of 2019, the total number of CT with more than 64 rows in China has nearly doubled.

Now the domestic ball tube market has completed a breakthrough from "0" to "1", and many excellent R&D manufacturers of core components of imaging equipment have begun to emerge.

last, Hu Yinfu said: "With the advancement of the localization of high-end medical equipment, it is crucial to fully localize the core components of imaging equipment. Although CT ball tube is a very subdivided track in the field of medical equipment, its market size is not small. According to our calculations, the global market size of CT ball tube has reached 8 billion dollars, while the domestic market size of CT ball tube has reached 8 billion yuan. In all categories of high-value medical consumables, its market size is second only to Orthopedic and vascular intervention.

In the future, with the continuous popularization of the application of CT machine equipment in China, the encouragement and guidance of policies, and the development of the ball tube industry, the ball tube, high-voltage sounder, and detector will usher in a period of rapid development. Zhishou Technology will also expand its product pipeline from the material and supply chain end to the ball tube technology of various technology types. "